Cheese and Dairy Products

Over the years, IAI has been involved in a wide range of projects within the agri-food industry, particularly in the dairy sector. Its expertise in the field has proved to be highly innovative and effective in developing the solutions indispensable this industry’s continuity. In today’s world, novel solutions and progressive problem-solving abilities are the driving force behind the success and growth of businesses. In order to be competitive, companies must innovate using new resources, techniques, references, and so on – this is an important challenge to face. Moreover, our expertise is concerned not only with the development or improvement of products and equipment, but also with the integration of existing processes and the optimization of production systems, including the adoption of new technologies. IAI’s market knowledge is an unrivalled asset when it comes to knowing how to move forward in the right direction.

Food and Pharmaceutical Processing Equipment

Expertise, innovation, versatility, and synergy between our team members: all of these characteristics allow IAI to offer you quality solutions in developing and installing food, pharmaceutical and biopharmaceutical processing technologies. We are able to provide you with a certificate of conformity proving our compliance with most FAT and SAT requirements, such as: Ra surface finish; washing ball coverings; baroscope inspection with videoscopy; dye penetrant tests; IQ and OQ, traceability (equipment, mill report, etc.). We also hold U, UM and National Board certifications. Manufactured equipment can be shipped with a Canadian registration number. Our welders and welding procedures are approved by the Government of Quebec’s authorized agency according to the qualification listed in section IX of the ASME code. The pharmaceutical and biotechnology sectors are two industrial areas subject to particularly high quality standards: We can offer production in accordance with the ASME standards, Section VIII; Division 1, as well as all ASME BPE-2002 requirements and CSA, cGMP, Agriculture Canada and USDA, and Health Canada and FDA standards.

Tanks and Silos

Tanks and Silos

IAI is today’s largest manufacturer of 3A certified tanks in Canada. IAI distinguishes itself from the competition with the implementation of its collaborative model, which is based first and foremost on mutual trust between us and our customers. This approach encourages the emergence of solutions capable of giving our customers a competitive edge while still operating within the strict regulations that are in place to protect confidentiality of information. IAI is dedicated to the development and turnkey delivery of this type of equipment. Furthermore, not only are we greatly familiar with the concerns associated with both development and delivery, but we are also aware of management imperatives and quality assurance throughout the entire process. IAI has ASME certification, U-stamp for pressurized tanks with CRN and National Board; as well as 3A certification for sanitary applications. IAI also manufactures its equipment according to the other codes: ULC, API, ASME BPE, and so on. Our facilities are equipped with advanced equipment and logistics systems (for example: dedicated unit, automated positioners, automated welding, handling equipment of very large capacity, etc.), standardized manufacturing methods, optimized supply management, and material flow control.

Mixers and Drums

For nearly seventy years, IAI has consistently been recognized as a leader in the industry. Every step of its growth has been achieved by keeping in mind the importance of quality service and the customer’s needs. IAI guarantees only quality service, both upstream in the design phases as well as downstream throughout the manufacturing, commissioning, and intallation stages. With superior workforce quality, our teams have the skills and experience to ensure the kind of production that meets your expectations. We have earned and maintained a reputation for unrivalled quality in the production of numerous models of mixers, cookers, and value-added processors, from small to very large capacity units. Our expertise in design and manufacturing is an indispensable asset for high-quality equipment and service during all phases of design, fabrication, installation and commissioning.

Reactors et processors

Reactors are designed to eliminate risks of contamination and to protect tanks from asepsis, some involving the production of highly sophisticated processing technologies such as bioreactors. There are many types of reactors used in different kinds of industries: agro-food, pharmaceutical, metallurgical, and energy, to only name a few examples. A reactor’s level of temperature control and operating pressure will depend on the type of task that is meant to be completed. The equipment’s operating pressure has implications for the manufacturing code that needs to be respected: ASME Section VIII, BPE, so on and so forth. Depending on the type of reactor, the control elements may for example include: sterility, pH measurements to ascertain pH levels, oxygen concentration, foam, and so on. Processors are reactors designed to provoke or accelerate a chemical process. Usually, they are thermally insulated and equipped with agitators as well as temperature and pressure control systems. These highly complex pieces of equipment require a high level of technical knowledge both in design and in manufacturing. IAI has a particularly sophisticated expertise in this field and has many achievements in regards to a vast range of reactors and processors. It is one of the biggest manufacturers of this kind of equipment for the agri-food industry in Canada.

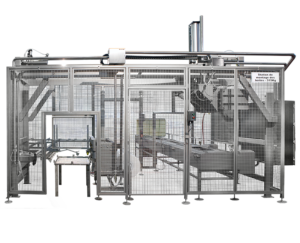

Packaging and Handling

Whether it is for solid products with automated systems, liquids with aseptic packaging, or air treatment, IAI is capable of designing a wide range of packaging and handling products that meet very high design and manufacturing standards. IAI is now recognized as one of the leading players in the field of conveyor systems. The Company has devoted significant R & D financial resources to the development of a vast array of equipment that may be needed to meet the productivity levels requirements of its customers. From intelligent systems such as sorting monorail to ingenious processing systems for the food and beverage industry, IAI can design and create the appropriate conveyor systems to suit your specific needs.