In recent years, a noteworthy evolution has taken place in conveyor systems performance. The improvements observed are mainly due to the emergence of value-added technologies, which is the result of development work aimed at creating highly specialized equipment: smart conveyors, process control, precision controlled movement, and so on. This technological development can be explained by two main factors. One is the industry’s ever-increasing demand in regards to the efficiency of their production processes. The second is due to the introduction of affordable automation and control technologies which revolutionized the way of designing and creating conveyor systems. Today, the IAI Group is recognized as one of the leading players in this field. The Company has devoted significant R & D financial resources to the development of a wide range of equipment that may be needed to achieve the level of productivity that the customers require.

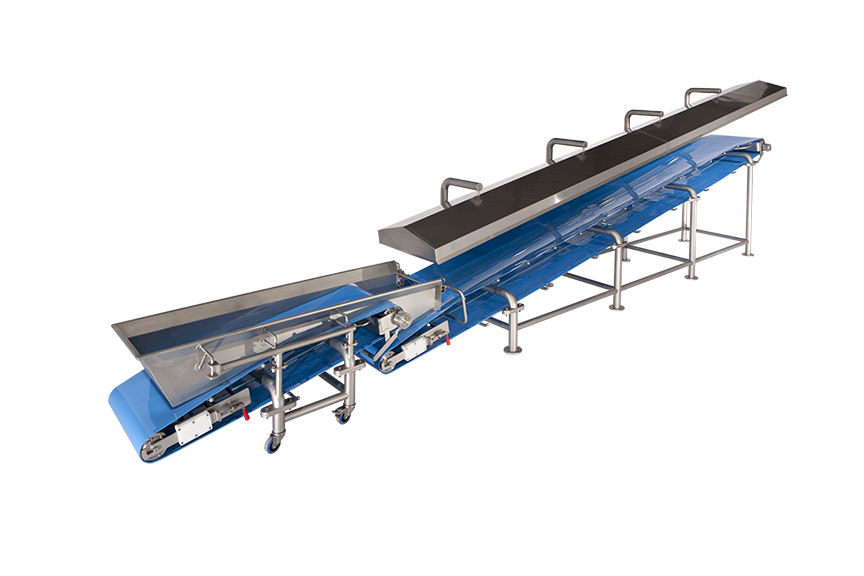

Mobile Sanitary Conveyor for the Food Industry

Example of a conveyor designed to fit the client's installations. Easy to clean, with an easily removable belt .

Conveyor and Press System for Food Products

This product is an example of a food processing unit with a fully automated continuous conveyor system. This vegetable press removes the maximum quantity of water from a cabbage through a continuous process using a cylinder-operated press, lessening the operators' workload and improving variances due to its constant spinning rate.

Fluidized Bed

High-throughput drying by displacement of dehydrated blueberries received from a continuous macerator. Risks of degradation and agglomeration of small fruits are minimized during displacement thanks to a drying tunnel equipped with a vibrating conveyor under a fluidized bed which is divided into separate sections. Each eaction is equipped with different temperature and air flow control.

Barrel Lift / Inverter

This PLC-controlled barrel lift/inverter is designed according to market needs. It includes a large number of options that makes it a versatile piece of equipment. It includes a high precision variable elevation system and speed control.

Elevator/Discharger

This elevator/discharger has been specifically designed to handle the customer's existing trays and to adapt it to the architecture and constraints inherent to the site's facilities.

Automated Sorting Conveyor System

This safe elevator / regulator was specifically designed for handling a customer's existing bins so as to adapt the system to architectural contraints

Conveyor Systems

IAI designs and manufactures a wide range of customized conveyor systems that are easy to clean and disassemble.

Conveyor Unit For Draining

This double conveyor system has an arrangement of the drip slots, points of product entry, and conical screws with adjustable speed. Its function is to presses food products in order to extract liquids and is meant to be integrated into a production line. Drainage is controlled by the unit's structure and screws, which ensures the desired final texture.